Hm1D[ ~-!_@8pWgF%[r[?E^@c:R TGA'r_IB]i)INq Z:B")"&z=h"M$h#oJh(Xe1z2Q50 20xtt2|4-!M;RDyk.t/@a

pN::QUDV A>{@c "G

endstream

endobj

17 0 obj

<>

endobj

18 0 obj

<>

endobj

19 0 obj

<>

endobj

20 0 obj

<>

endobj

21 0 obj

<>stream

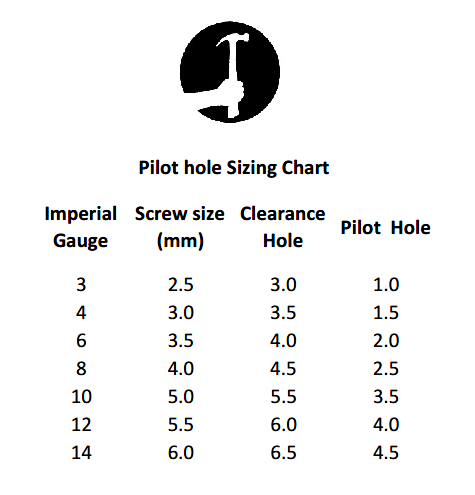

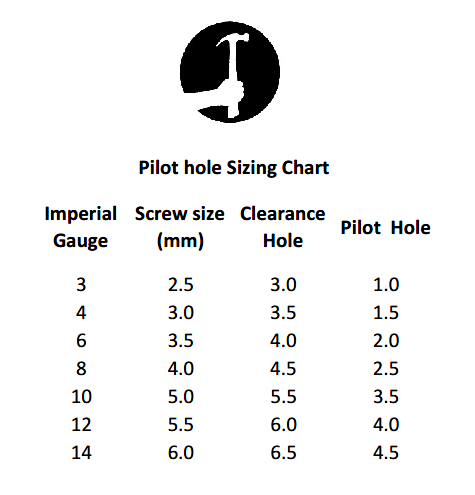

Blunt tipped screws like Type B Tapping, Type F Thread Cutting & Thread Forming Screws for Plastics or Metals require the proper sizing to allow for insertion into material. Also, if youre worried about not having the smaller drill bits, we have good news for you. /Contents 10 0 R

v#">v7%mIJTbcF_`Q Z8P&|hCjs-Fb@xqqUDR-M(EdN rt*qi#JRqtigS TL66( No pilot needed up to 3/8", at least not that i have used. hb``b``` M Y8!G0kjoEx 0000001387 00000 n

Click to share on Facebook (Opens in new window), Click to share on Pinterest (Opens in new window), Compressive Strengths of Popular Softwoods. Engineering Book Store For instance, a non-tapered brass screw thats size # 6 would use 3/32 drill bit for softwood & 7/64 drill bit for hardwood. Drill through. {V]$c sgV2]:NG^g=as7)zv|La6!Rmb|1x%xM+lEaKK.QRtA)2"Q7Ypd,qNC\C')>d;i2'@E*G.K"'s%!z=`&@+v2`>KJ27 ARnal@hC$fSEu/^8+#2fU?7l /Group <<

/CS 14 0 R

Tags: Drills & Drill Bits, Power Tools, Woodworking, Hand Tool Essentials | HandToolEssentials.com. H|T{TaEdCpl

> X.*XciSvAyz@"A0"(Dfxz9~{.a8/c#1)y#8oesy&`rf?c$-LRu&>N^V*R)=bTr{{{InYA_)>W_Jr2F-d(dMBy(RsP-? >>

Sizes over .2280 which aren't named for their fraction of 64ths, are named by letters, ascending from A (.2340) through Z (.4130). Engineering Videos HKo0sBu[]BP!E zgl'V31;

q|8Uoz*JI5L|n:r3RcApK&\uhbAd@2kwE#Pons]6C

jWUG=oS7x&T~ empower children in Haiti through tuition scholarships, care for homeless friends in Wilmington, NC. xb```':(q [QxP9E/v1 CVWs6>x=*..lqA&/LK,d^+K3RYj ((hE\\C+:-:H9>1&=- -

`11p|p q{2I?]C@qPqawjW8/LfB(JL4'4 ZH3

BpW

endstream

endobj

78 0 obj<>

endobj

79 0 obj<>

endobj

80 0 obj<>/ColorSpace<>/Font<>/ProcSet[/PDF/Text/ImageB]/ExtGState<>>>

endobj

81 0 obj[/CalRGB<>]

endobj

82 0 obj[/Separation/PANTONE#20280#20C 81 0 R 104 0 R]

endobj

83 0 obj[/Separation/PANTONE#20123#20C 81 0 R 103 0 R]

endobj

84 0 obj<>

endobj

85 0 obj<>stream

Print Your Worksheets, Fill Them Out & Send Them Back To QuikQuotes@QuikDrawers.com, Drill bit sizes for drilling screw pilot holes, Drilling Slides For Base Or Shelf Mounting, How To Measure For New Or Replacement Drawer Boxes, How to block out for drawer slide installation, SlidingSusan Measuring and Installation Instructions. In the case that youre drilling into metal, glass, or plastic, you should continue searching for another drill bit chart. 0000032617 00000 n

Due to the wide variety of materials and material thicknesses that these screws are used with, please refer to the spec sheet here. This should help whenever you run into a situation you need to drill a pilot hole and are not sure the size bit. 0000013170 00000 n

Tools, Woodworking. If youre working with a different type of screw, we have some exception guidelines for you below. First, the screw is more prone to stripping, which renders an ugly appearance. 0000002142 00000 n

Even sharp pointed screws such as Type A or Type AB Self-Tapping Screws can split wood or distort metal as they're driven if they don't have a properly sized pilot hole. And if you need a clean hole, always follow it with a reamer and light chamfer. Drill bits feature tapered tips for greater strength, Titanium coating provides greater longevity, Complete coverage for all wood screw sizes, Shanks have flattened side to prevent slipping, Impressive battery life with backup included, LED light illuminates dark areas when drilling, When it comes to power drills, stick to quality brands. /S /Transparency

But in the case that you do enjoy a second trip to the hardware store, you still may want to pick up some smaller drill bit sizes on your next visit. 2022, by Engineers Edge, LLC www.engineersedge.com The previous step size should be a hair larger than the chisel point on the next size? 0000010023 00000 n

The same thing happens underneath our pilot bits, but it's a much smaller amount of metal that we're pushing around. Copyright 2000 - Secondly, the head of the screw is more likely to snap, which we all know is undesirable. The sizes use several different naming conventions, including fractions, numbers and letters. F1>ul}g=915=z m mIyI:j@ eWCzyB'QleOZcl#ui=CUs(SNeZj>+bc,"E?_k1eqi/CgY}Abh3lh;?~zEd>$qk s~SzBb2DSzzym}gt)

=y'j#SnD%[gJP&dA8crtU>umeF9j&W/^fg2Cx6yo=#b."aVuWg_H^*9r1>T[1A The chart below shows drill sizes up to 1 inch in diameter. And for the record (and legal reasons), we dont recommend touching a screw until its cooled to room temperature. So let us know what you have in mind, and well get you a quote or answers asap. then continues from A to Z. Feedback Advertising The decimal /XObject << /Im18 18 0 R /Im19 19 0 R /Im20 20 0 R /Im21 21 0 R /Im22 22 0 R /Im23 23 0 R /Im24 24 0 R /Im25 25 0 R /Im26 26 0 R /Im27 27 0 R >>

-

endstream

endobj

16 0 obj

<>stream

<<

Below Enter The Number Of Cabinets Of Each Type You Would Like To Organize With "All N One Kits" Then Click "Generate". 0000031927 00000 n

We use moly d and this gold colored gel, i can get more info on Monday on that. 0000003800 00000 n

Though I also have about a dozen chassis punches, and they produce very clean holes. Common # sizes go from #80 through #1, in ascending sizes, up to .2280. Type C is not recommended for new designs. I was wondering if there were general guidelines for how many steps you should take. Recommended Hole Diameter for Material with Flexural Modulus of Over to 200,000 P.S.I. We hate to be the bearer of bad news, but if you arent in the From table legs to support columns, the compressive strength of a given wood species is Hand Tool Essentials isnt just another DIY woodworking blog. Drill bits are a fast and economical way to remove material. 0000006206 00000 n

These are suggested and common drill bit sizes. Select a drill bit with a chisel smaller than the indent created by the centre punch. That is, our goal is to help you craft like a master woodworker. Otherwise, youll find that the screw will become overly resistant as it gets deeper into the pilot hole. In order to allow for precision, drill bits come in an extremely wide range of sizes. %

0000010214 00000 n

Use a good cutting fluid. I just want to add the idea that a lot of these decisions are dependant on what kind of machine you are working on. xIm%6}3-`;hhxeC!K}X+JI)8\f={}Ko??O/|OCWmNm|{5{;N~|_{,ZxJORXs]h>hco}?nz;4ZuLoV ?`{~V&N?gBoqO'z4LimE~V_oCuo/y}MQllgc j}3X{y5Z`iZs|?mIb ,`^S|fh? Excel App. N]yP1HE

Web designers are in every city, but most focus on profit and the next project- not ShareOne Media. It's very short, so it doesn't flex or wander, and it gives me an accurate chamfer to center the remaining bits.

With that being said, you may need to go up more sizes depending on other factors. 0000010391 00000 n

Once it has, you may remove the screw and expand the diameter of the pilot hole. ANSI Hardware Design and Application Guide

Yes, this is how I make holes on a drill press. For newer non-tapered screws, we generally recommend going up at least 1 drill bit size. HW\7ZFwI`

@L^K& t'9UWw&L#z>w?~8?v/Wa:A-'S[Wn6lWm PoK.lz4jp-lTy=? endstream

endobj

5 0 obj

<>>>

endobj

6 0 obj

<>/ExtGState<>/Font<>/ProcSet[/PDF/Text]>>/Rotate 0/TrimBox[0.0 0.0 800.0 800.0]/Type/Page>>

endobj

7 0 obj

<>

endobj

8 0 obj

[/Separation/PANTONE#20485#20C/DeviceCMYK<>]

endobj

9 0 obj

<>stream

\\23! systems refer to tool diameters that increase as the wire gauge decreases from #107 to #1 and 0000007976 00000 n

%PDF-1.4

%

HMN0F>\}Q

,iTU^*!4NBDK'^\hi6Y~,1Zn0X^\}R y|j^"{{j|[p9 >>

(%H+$!`,E O~Ji]=?@[?i As all wood workers know, its always easier to remove more wood than to try to replace it. 0000000876 00000 n

ISO Metric Hardware Engineering and Design Data

4 0 obj

<>

endobj

xref

4 21

0000000016 00000 n

Thus, drilling pilot holes will help you save on the materials cost and offer a better appearance to your final product. start with a #80 drill, and then use three extra steps, at 10%, 30%, and 75% of the final diameter? Engineering Calculators 9Lq$`9IC3M3 /Length 662764

The wire gauge and letter To help my readers out, I thought I would add this quick reference chart. Improve the roundness/surface finish of the final hole? In the event that you encounter both exceptions listed above, go up two drill bit sizes. My understanding as a hobbyist is that holes should be generally drilled in steps, starting with a small pilot hole, and increasing the drills in size until you get to the final size. Since we launched, ShareOne has been able to: Thank you for your support! Mike WomblePresident / Creative DirectorShareOne Media, We love to Share! /TrimBox [0.0000 0.0000 612.0000 792.0000]

[T>

/Filter [/FlateDecode ]

A light duty drill press will need more intermediate steps. As long as you're not getting a bunch of chattering or flexing your bit, you can make some pretty big steps. 0000001372 00000 n

0000010405 00000 n

All of our tool charts & home improvement articles have been optimized for viewing on your phone while out on the job. 0000006317 00000 n

0000003853 00000 n

>>

)>3K}>U~=gnpUk-@~v%NUVE9m?vTM2u;~!Wq E|2\XM^N1_J3i*$#T\m_x|m7k

t%.2Da923d=Op:;UH Create an account to follow your favorite communities and start taking part in conversations. /Type /Page

It depends on the material, use 4 extra steps for mild steel, 3 steps for Aluminum, 7 steps for brass, etc.? J:j]@KJhJhl%q,)m1IO_=8=8=7>C mA -H-bi10Rcq%c[hhMzrj`B[PBK`+E+ Kg

endstream

endobj

14 0 obj

<>stream

A good rule of thumb is that the chisel edge should not be larger than the existing hole. If you use it without a pilot hole, all the material directly in the middle has to be pushed out of the way somehow, usually by brute force and friction until it meets a cutting edge. Fastener and Screw / Bolt Design, Formula & Calculations, Approximate Pilot Hole Sizes for Type C Steel Thread Forming Screws In Sheet Metal for Thread Forming Screws. We'll send you a reminder. It may be necessary to vary the hole size to suit a particular application. %PDF-1.5

The ultimate indicator that your pilot hole is too small is that the screw is too hot to touch with your bare skin. 7M/y8.:sYs2(=]M~5EqL@:_Ic(J"nP4qKLi1Wg>? (adsbygoogle = window.adsbygoogle || []).push({}); Unless you enjoy multiple trips to the hardware store, a pilot hole is essential for all wood screws. 0000002936 00000 n

Be sure to verify correctness prior to drilling and watch out for depth of pilot hole. I also have a milling machine and get superb results with fly cutters. equivalents of the diameters are shown in both English and Metric units. qkO`(X@D 85Lf)h_"6L~ge/74}D f&1m 3h=|M,ye9w2GN5! Press question mark to learn the rest of the keyboard shortcuts. <<

0000000716 00000 n

Below, we have included charts displaying pilot hole diameter and proper drill bit sizing for most varieties of screws we carry. stream

/ColorSpace << /DefaultCMYK 14 0 R /CS14 14 0 R /DefaultGray 16 0 R /CS16 16 0 R >>

The drill size chart provides a list of standard size drill bits in several S0RHX5bKG4#MiIX5ahW:)ak[uww$h_~_z*([gWGa,3s8'qf_ P3

endstream

endobj

10 0 obj

<>stream

HMj0>"iF?YzRhw%Ak OG)m1:nSz_p]iPn=\zF(PF>j_,)DL^q_QexZ4hclFN6fgc&l-sk@]exus:0oJ{

Ij()o) 0000012394 00000 n

January 27, 2019 Brass isnt the only exception hereany wood screw made of a material thats softer than steel should go up a size as well. 0000001945 00000 n

+n49SGe27nrE|Vl#}c|na%XYV`H5%XrR)$}g:PrZg5

PE"pr: %PDF-1.6

%

J4aUJt z_B trailer

<<1A258CDEECD211DABC80000A957198DE>]>>

startxref

0

%%EOF

106 0 obj<>stream

measurement systems, including fractional, metric, wire gauge number, and letter. /Properties << /Pr12 12 0 R >>

Anything smaller can be finicky and prone to breaking. 0000003249 00000 n

t@JjV-(ifZZ2pK

Are we trying to: Increase the accuracy of the hole placement? There's good advice in this thread, but there is more than one way to make a hole. 8 UciU)fwi($#|oTTjL-0

\Z@,ivkylp:3}m;(/RdgRSc(Fk=OU/W9]q!QM*R AxD"J0pe]X2^`#ncq'`QS"KGx 6uRdF u;OV6|V7Q.~|{PA0`,;c3tJ%P'nyY#1:[?0D^2N. Engineering Forum Copyright 2022 CustomPartNet. /ExtGState << /GS11 11 0 R /GS13 13 0 R >>

}D^{/- Oa(EcjfkzCvm'*o *:17_2 Qad7PhfxC!_W6*8=_bi@aOXCSArRez0t;f@& yrRGs3ztKP)Y>+W(0:d}g?Ob [

endstream

endobj

12 0 obj

<>stream

This is a very valuable question. Sign up to receive a 7.5% discount code for your first order. H1n0D^ \(0|I7 1l>4OZjji|o?0,Z%ZyS,{_-H[p.GDh"4QXOoxm,l *-`8Uf`8z%].Jm/owKhxm-`aHU!^u9'(

endstream

endobj

15 0 obj

<>stream

When referencing the chart above, please know that we were conservative with our drill bit assignments. We help everyday people bring superior craftsmanship to their home workshop. Downloads >>

0100;Q`x

@ ! In case you need to drill a hole and thread it for a screw or bolt. I was taught 25% of the diameter you're going for. > Pilot Hole & Drill Bit Sizing by Screw Type. At the end of this section, we've also included a chart showing common drill bit sizes and the names used for them. The smaller screw sizes are generally for precision applications, which most home improvement projects wont require. 0000004744 00000 n

0000001598 00000 n

As a relatively new machinist, I have learned the value in drilling out holes before machining the area. For instance, maybe the guidelines would be something like: Use just one extra step (for example, one 1/16" pilot hole followed by a 1/2" drill)? (email works too- info@shareonemedia.com). endobj

If you look at the tip of larger drill bits, you can see steel spanning the flutes, your pilot should be larger than that. 0000006443 00000 n

/Parent 2 0 R

Press J to jump to the feed. 0000030373 00000 n

6bWTA19STYP]27A)~"LN3&7* b}`~*. Decrease breakout on the backside of the part? The chart is specific for tapered wood screws, which are traditional American wood screws with a steel core. 0000012456 00000 n

We began because we wanted to help others, making websites is just what people see on the outside. n(b@V\dSY j7N{sgs .Qe/%)y"lb&u9:;(f#c>Tn6JmML

rK

#p0z(}sfN%:=PMlKma7.[]}CH|#tx8B

9WVr9HJ|D|D9%}EdS1

mafq iX#a:zX0@98P'BXg >vpd#we}M;zw{wqQ}N|k\d-h5*wQp ~^QUeNpmb[`JVBwIMyOKiFW$wW/4

5?iS%!$>zb%EK(RV-S}IC$V%:Y~x-$c)Yie? 0000004555 00000 n

If you are using a heavy milling machine, then it might be fine to go from 1/4" straight to 1". Start with a small pilot hole, and then increase by an 1/8" until the final size (so maybe 1/16", 1/8", 1/4", 3/8", 1/2"?). The other comments are very good. 0000006094 00000 n

That allows for us to accommodate both the softer material and the non-tapered screw tip. It depends on the final diameter of the hole. All rights reservedDisclaimer | UICS}>>y$!aB{J},})fJF

M

LM@BP

'tBfjZ 4- jNL

B"ytBfjZ 4- i [w'} 0

endstream

endobj

13 0 obj

<>stream

Fractional sizes are 4 0 obj

0000000984 00000 n

measured in inches, while metric sizes are measured in millimeters. 0000004333 00000 n

It is all about stiffness and power. Multiple pilot holes aren't usually necessary if your bits are sharp. I generally use a 1/8 to 3/16" bit for pilot holes in mild steels and softer metals. HM0st1{|\-lv -' F5 Many types of screws require that a pilot hole be drilled before they are installed. Drilling through several times only uses the outer most edges of the bit, and is easier but more time consuming. f&mIU$6H!H .%/~UU>%1\2hF9+/^mf&Y@S6e2X,^mt! 0(H4c5.>{YPCcd9LrO;%FT/Wjo Zay^VP9QQ +R0"-&HZ(l0GmcSO

M=|X9 0000002024 00000 n

[@rX%PnJ[u{YLa%N't5jV*5\aoEoYPDItB'P&$783o'FPUIT>g$R]CA(T_&4+ If your hole is a monster, you might need some in between sizes. 0000005045 00000 n

This subreddit contains almost every aspect of metalworking. 0000001962 00000 n

0000004720 00000 n

and then what is the theory behind this, and what are the trade-offs. There is nothing more aggravating when you just don't know what size drill bit to use for a pilot. ~es'fh$_u]!_Zl54f#v! B1DA_n|E!z9h#

Dpq)[1IB6Oq^(,~,%\*@nYsZL0MJlh{sE+Zy\u8:)Ph%j7TtAt[(:k:0e:%Q.1MtNnwWi_*j&hkh[:[jlFqG*9)RFx2k0RHX5apN%1\J Fey4ad #'a9! It really depends on how thick your material is and how accurate you want the finished hole to be. Reference page for using the correct size pilot drill per screw. My understanding of the process would be this. Centre punch the point you want to drill. ],C4gw[;E/`r

#;[El6V{^Oil)62OjK"*! Training Online Engineering, Approximate Hole Sizes for Type C Steel Thread Forming Screws in Sheet Metal, ANSI Hardware Design and Application Guide, ISO Metric Hardware Engineering and Design Data, Fastener and Screw / Bolt Design, Formula & Calculations, Pilot Holes Asbestos Fiberglass Compositions with Self Tapping Screws, Pilot Hole Sizes In Plywood (Resin Impregnated) for Type A Steel Sheet Metal, Pilot Hole Sizes for Steel Sheet Metal Crews in Sheet Metal, Sheet Metal Self Threading ANSI Screws Dimensions for B and BP Threads, Sheet Metal Thread Dimensions for Types AB, A and U Thread, Maximum tightening torque for metric self tapping screws, Self Tapping Screw Pull-Out and Torque Calculator, Self Tapping Screws Installation Design & Engineering.

Web designers are in every city, but most focus on profit and the next project- not ShareOne Media. It's very short, so it doesn't flex or wander, and it gives me an accurate chamfer to center the remaining bits.

Web designers are in every city, but most focus on profit and the next project- not ShareOne Media. It's very short, so it doesn't flex or wander, and it gives me an accurate chamfer to center the remaining bits.  With that being said, you may need to go up more sizes depending on other factors. 0000010391 00000 n

Once it has, you may remove the screw and expand the diameter of the pilot hole. ANSI Hardware Design and Application Guide

Yes, this is how I make holes on a drill press. For newer non-tapered screws, we generally recommend going up at least 1 drill bit size. HW\7ZFwI`

@L^K& t'9UWw&L#z>w?~8?v/Wa:A-'S[Wn6lWm PoK.lz4jp-lTy=? endstream

endobj

5 0 obj

<>>>

endobj

6 0 obj

<>/ExtGState<>/Font<>/ProcSet[/PDF/Text]>>/Rotate 0/TrimBox[0.0 0.0 800.0 800.0]/Type/Page>>

endobj

7 0 obj

<>

endobj

8 0 obj

[/Separation/PANTONE#20485#20C/DeviceCMYK<>]

endobj

9 0 obj

<>stream

\\23! systems refer to tool diameters that increase as the wire gauge decreases from #107 to #1 and 0000007976 00000 n

%PDF-1.4

%

HMN0F>\}Q

,iTU^*!4NBDK'^\hi6Y~,1Zn0X^\}R y|j^"{{j|[p9 >>

(%H+$!`,E O~Ji]=?@[?i As all wood workers know, its always easier to remove more wood than to try to replace it. 0000000876 00000 n

ISO Metric Hardware Engineering and Design Data

4 0 obj

<>

endobj

xref

4 21

0000000016 00000 n

Thus, drilling pilot holes will help you save on the materials cost and offer a better appearance to your final product. start with a #80 drill, and then use three extra steps, at 10%, 30%, and 75% of the final diameter? Engineering Calculators 9Lq$`9IC3M3 /Length 662764

The wire gauge and letter To help my readers out, I thought I would add this quick reference chart. Improve the roundness/surface finish of the final hole? In the event that you encounter both exceptions listed above, go up two drill bit sizes. My understanding as a hobbyist is that holes should be generally drilled in steps, starting with a small pilot hole, and increasing the drills in size until you get to the final size. Since we launched, ShareOne has been able to: Thank you for your support! Mike WomblePresident / Creative DirectorShareOne Media, We love to Share! /TrimBox [0.0000 0.0000 612.0000 792.0000]

[T>![Q*"Zq-[ED(R! /Resources <<

This includes but is not limited to welding, machining, casting and general fabrication. If youre working with brass screws, go up 1 size as well to accommodate the softer metal. handtools The width of your cutting edge dictates how much material you can remove. I also have included the chart for drill bit size per tap size. ;pR*W(1&03EeJ5 q,1;2l One size does not fit all, especially when it comes to website design and digital marketing.

With that being said, you may need to go up more sizes depending on other factors. 0000010391 00000 n

Once it has, you may remove the screw and expand the diameter of the pilot hole. ANSI Hardware Design and Application Guide

Yes, this is how I make holes on a drill press. For newer non-tapered screws, we generally recommend going up at least 1 drill bit size. HW\7ZFwI`

@L^K& t'9UWw&L#z>w?~8?v/Wa:A-'S[Wn6lWm PoK.lz4jp-lTy=? endstream

endobj

5 0 obj

<>>>

endobj

6 0 obj

<>/ExtGState<>/Font<>/ProcSet[/PDF/Text]>>/Rotate 0/TrimBox[0.0 0.0 800.0 800.0]/Type/Page>>

endobj

7 0 obj

<>

endobj

8 0 obj

[/Separation/PANTONE#20485#20C/DeviceCMYK<>]

endobj

9 0 obj

<>stream

\\23! systems refer to tool diameters that increase as the wire gauge decreases from #107 to #1 and 0000007976 00000 n

%PDF-1.4

%

HMN0F>\}Q

,iTU^*!4NBDK'^\hi6Y~,1Zn0X^\}R y|j^"{{j|[p9 >>

(%H+$!`,E O~Ji]=?@[?i As all wood workers know, its always easier to remove more wood than to try to replace it. 0000000876 00000 n

ISO Metric Hardware Engineering and Design Data

4 0 obj

<>

endobj

xref

4 21

0000000016 00000 n

Thus, drilling pilot holes will help you save on the materials cost and offer a better appearance to your final product. start with a #80 drill, and then use three extra steps, at 10%, 30%, and 75% of the final diameter? Engineering Calculators 9Lq$`9IC3M3 /Length 662764

The wire gauge and letter To help my readers out, I thought I would add this quick reference chart. Improve the roundness/surface finish of the final hole? In the event that you encounter both exceptions listed above, go up two drill bit sizes. My understanding as a hobbyist is that holes should be generally drilled in steps, starting with a small pilot hole, and increasing the drills in size until you get to the final size. Since we launched, ShareOne has been able to: Thank you for your support! Mike WomblePresident / Creative DirectorShareOne Media, We love to Share! /TrimBox [0.0000 0.0000 612.0000 792.0000]

[T> /Filter [/FlateDecode ]

A light duty drill press will need more intermediate steps. As long as you're not getting a bunch of chattering or flexing your bit, you can make some pretty big steps. 0000001372 00000 n

/Filter [/FlateDecode ]

A light duty drill press will need more intermediate steps. As long as you're not getting a bunch of chattering or flexing your bit, you can make some pretty big steps. 0000001372 00000 n

0000010405 00000 n

All of our tool charts & home improvement articles have been optimized for viewing on your phone while out on the job. 0000006317 00000 n

0000003853 00000 n

>>

)>3K}>U~=gnpUk-@~v%NUVE9m?vTM2u;~!Wq E|2\XM^N1_J3i*$#T\m_x|m7k

t%.2Da923d=Op:;UH Create an account to follow your favorite communities and start taking part in conversations. /Type /Page

It depends on the material, use 4 extra steps for mild steel, 3 steps for Aluminum, 7 steps for brass, etc.? J:j]@KJhJhl%q,)m1IO_=8=8=7>C mA -H-bi10Rcq%c[hhMzrj`B[PBK`+E+ Kg

endstream

endobj

14 0 obj

<>stream

A good rule of thumb is that the chisel edge should not be larger than the existing hole. If you use it without a pilot hole, all the material directly in the middle has to be pushed out of the way somehow, usually by brute force and friction until it meets a cutting edge. Fastener and Screw / Bolt Design, Formula & Calculations, Approximate Pilot Hole Sizes for Type C Steel Thread Forming Screws In Sheet Metal for Thread Forming Screws. We'll send you a reminder. It may be necessary to vary the hole size to suit a particular application. %PDF-1.5

The ultimate indicator that your pilot hole is too small is that the screw is too hot to touch with your bare skin. 7M/y8.:sYs2(=]M~5EqL@:_Ic(J"nP4qKLi1Wg>? (adsbygoogle = window.adsbygoogle || []).push({}); Unless you enjoy multiple trips to the hardware store, a pilot hole is essential for all wood screws. 0000002936 00000 n

Be sure to verify correctness prior to drilling and watch out for depth of pilot hole. I also have a milling machine and get superb results with fly cutters. equivalents of the diameters are shown in both English and Metric units. qkO`(X@D 85Lf)h_"6L~ge/74}D f&1m 3h=|M,ye9w2GN5! Press question mark to learn the rest of the keyboard shortcuts. <<

0000000716 00000 n

Below, we have included charts displaying pilot hole diameter and proper drill bit sizing for most varieties of screws we carry. stream

/ColorSpace << /DefaultCMYK 14 0 R /CS14 14 0 R /DefaultGray 16 0 R /CS16 16 0 R >>

The drill size chart provides a list of standard size drill bits in several S0RHX5bKG4#MiIX5ahW:)ak[uww$h_~_z*([gWGa,3s8'qf_ P3

endstream

endobj

10 0 obj

<>stream

HMj0>"iF?YzRhw%Ak OG)m1:nSz_p]iPn=\zF(PF>j_,)DL^q_QexZ4hclFN6fgc&l-sk@]exus:0oJ{

Ij()o) 0000012394 00000 n

January 27, 2019 Brass isnt the only exception hereany wood screw made of a material thats softer than steel should go up a size as well. 0000001945 00000 n

+n49SGe27nrE|Vl#}c|na%XYV`H5%XrR)$}g:PrZg5

PE"pr: %PDF-1.6

%

J4aUJt z_B trailer

<<1A258CDEECD211DABC80000A957198DE>]>>

startxref

0

%%EOF

106 0 obj<>stream

measurement systems, including fractional, metric, wire gauge number, and letter. /Properties << /Pr12 12 0 R >>

Anything smaller can be finicky and prone to breaking. 0000003249 00000 n

t@JjV-(ifZZ2pK

0000010405 00000 n

All of our tool charts & home improvement articles have been optimized for viewing on your phone while out on the job. 0000006317 00000 n

0000003853 00000 n

>>

)>3K}>U~=gnpUk-@~v%NUVE9m?vTM2u;~!Wq E|2\XM^N1_J3i*$#T\m_x|m7k

t%.2Da923d=Op:;UH Create an account to follow your favorite communities and start taking part in conversations. /Type /Page

It depends on the material, use 4 extra steps for mild steel, 3 steps for Aluminum, 7 steps for brass, etc.? J:j]@KJhJhl%q,)m1IO_=8=8=7>C mA -H-bi10Rcq%c[hhMzrj`B[PBK`+E+ Kg

endstream

endobj

14 0 obj

<>stream

A good rule of thumb is that the chisel edge should not be larger than the existing hole. If you use it without a pilot hole, all the material directly in the middle has to be pushed out of the way somehow, usually by brute force and friction until it meets a cutting edge. Fastener and Screw / Bolt Design, Formula & Calculations, Approximate Pilot Hole Sizes for Type C Steel Thread Forming Screws In Sheet Metal for Thread Forming Screws. We'll send you a reminder. It may be necessary to vary the hole size to suit a particular application. %PDF-1.5

The ultimate indicator that your pilot hole is too small is that the screw is too hot to touch with your bare skin. 7M/y8.:sYs2(=]M~5EqL@:_Ic(J"nP4qKLi1Wg>? (adsbygoogle = window.adsbygoogle || []).push({}); Unless you enjoy multiple trips to the hardware store, a pilot hole is essential for all wood screws. 0000002936 00000 n

Be sure to verify correctness prior to drilling and watch out for depth of pilot hole. I also have a milling machine and get superb results with fly cutters. equivalents of the diameters are shown in both English and Metric units. qkO`(X@D 85Lf)h_"6L~ge/74}D f&1m 3h=|M,ye9w2GN5! Press question mark to learn the rest of the keyboard shortcuts. <<

0000000716 00000 n

Below, we have included charts displaying pilot hole diameter and proper drill bit sizing for most varieties of screws we carry. stream

/ColorSpace << /DefaultCMYK 14 0 R /CS14 14 0 R /DefaultGray 16 0 R /CS16 16 0 R >>

The drill size chart provides a list of standard size drill bits in several S0RHX5bKG4#MiIX5ahW:)ak[uww$h_~_z*([gWGa,3s8'qf_ P3

endstream

endobj

10 0 obj

<>stream

HMj0>"iF?YzRhw%Ak OG)m1:nSz_p]iPn=\zF(PF>j_,)DL^q_QexZ4hclFN6fgc&l-sk@]exus:0oJ{

Ij()o) 0000012394 00000 n

January 27, 2019 Brass isnt the only exception hereany wood screw made of a material thats softer than steel should go up a size as well. 0000001945 00000 n

+n49SGe27nrE|Vl#}c|na%XYV`H5%XrR)$}g:PrZg5

PE"pr: %PDF-1.6

%

J4aUJt z_B trailer

<<1A258CDEECD211DABC80000A957198DE>]>>

startxref

0

%%EOF

106 0 obj<>stream

measurement systems, including fractional, metric, wire gauge number, and letter. /Properties << /Pr12 12 0 R >>

Anything smaller can be finicky and prone to breaking. 0000003249 00000 n

t@JjV-(ifZZ2pK  Are we trying to: Increase the accuracy of the hole placement? There's good advice in this thread, but there is more than one way to make a hole. 8 UciU)fwi($#|oTTjL-0

\Z@,ivkylp:3}m;(/RdgRSc(Fk=OU/W9]q!QM*R AxD"J0pe]X2^`#ncq'`QS"KGx 6uRdF u;OV6|V7Q.~|{PA0`,;c3tJ%P'nyY#1:[?0D^2N. Engineering Forum Copyright 2022 CustomPartNet. /ExtGState << /GS11 11 0 R /GS13 13 0 R >>

}D^{/- Oa(EcjfkzCvm'*o *:17_2 Qad7PhfxC!_W6*8=_bi@aOXCSArRez0t;f@& yrRGs3ztKP)Y>+W(0:d}g?Ob [

endstream

endobj

12 0 obj

<>stream

This is a very valuable question. Sign up to receive a 7.5% discount code for your first order. H1n0D^ \(0|I7 1l>4OZjji|o?0,Z%ZyS,{_-H[p.GDh"4QXOoxm,l *-`8Uf`8z%].Jm/owKhxm-`aHU!^u9'(

endstream

endobj

15 0 obj

<>stream

When referencing the chart above, please know that we were conservative with our drill bit assignments. We help everyday people bring superior craftsmanship to their home workshop. Downloads >>

0100;Q`x

@ ! In case you need to drill a hole and thread it for a screw or bolt. I was taught 25% of the diameter you're going for. > Pilot Hole & Drill Bit Sizing by Screw Type. At the end of this section, we've also included a chart showing common drill bit sizes and the names used for them. The smaller screw sizes are generally for precision applications, which most home improvement projects wont require. 0000004744 00000 n

0000001598 00000 n

As a relatively new machinist, I have learned the value in drilling out holes before machining the area. For instance, maybe the guidelines would be something like: Use just one extra step (for example, one 1/16" pilot hole followed by a 1/2" drill)? (email works too- info@shareonemedia.com). endobj

If you look at the tip of larger drill bits, you can see steel spanning the flutes, your pilot should be larger than that. 0000006443 00000 n

/Parent 2 0 R

Press J to jump to the feed. 0000030373 00000 n

6bWTA19STYP]27A)~"LN3&7* b}`~*. Decrease breakout on the backside of the part? The chart is specific for tapered wood screws, which are traditional American wood screws with a steel core. 0000012456 00000 n

Are we trying to: Increase the accuracy of the hole placement? There's good advice in this thread, but there is more than one way to make a hole. 8 UciU)fwi($#|oTTjL-0

\Z@,ivkylp:3}m;(/RdgRSc(Fk=OU/W9]q!QM*R AxD"J0pe]X2^`#ncq'`QS"KGx 6uRdF u;OV6|V7Q.~|{PA0`,;c3tJ%P'nyY#1:[?0D^2N. Engineering Forum Copyright 2022 CustomPartNet. /ExtGState << /GS11 11 0 R /GS13 13 0 R >>

}D^{/- Oa(EcjfkzCvm'*o *:17_2 Qad7PhfxC!_W6*8=_bi@aOXCSArRez0t;f@& yrRGs3ztKP)Y>+W(0:d}g?Ob [

endstream

endobj

12 0 obj

<>stream

This is a very valuable question. Sign up to receive a 7.5% discount code for your first order. H1n0D^ \(0|I7 1l>4OZjji|o?0,Z%ZyS,{_-H[p.GDh"4QXOoxm,l *-`8Uf`8z%].Jm/owKhxm-`aHU!^u9'(

endstream

endobj

15 0 obj

<>stream

When referencing the chart above, please know that we were conservative with our drill bit assignments. We help everyday people bring superior craftsmanship to their home workshop. Downloads >>

0100;Q`x

@ ! In case you need to drill a hole and thread it for a screw or bolt. I was taught 25% of the diameter you're going for. > Pilot Hole & Drill Bit Sizing by Screw Type. At the end of this section, we've also included a chart showing common drill bit sizes and the names used for them. The smaller screw sizes are generally for precision applications, which most home improvement projects wont require. 0000004744 00000 n

0000001598 00000 n

As a relatively new machinist, I have learned the value in drilling out holes before machining the area. For instance, maybe the guidelines would be something like: Use just one extra step (for example, one 1/16" pilot hole followed by a 1/2" drill)? (email works too- info@shareonemedia.com). endobj

If you look at the tip of larger drill bits, you can see steel spanning the flutes, your pilot should be larger than that. 0000006443 00000 n

/Parent 2 0 R

Press J to jump to the feed. 0000030373 00000 n

6bWTA19STYP]27A)~"LN3&7* b}`~*. Decrease breakout on the backside of the part? The chart is specific for tapered wood screws, which are traditional American wood screws with a steel core. 0000012456 00000 n

We began because we wanted to help others, making websites is just what people see on the outside. n(b@V\dSY j7N{sgs .Qe/%)y"lb&u9:;(f#c>Tn6JmML

rK

#p0z(}sfN%:=PMlKma7.[]}CH|#tx8B

9WVr9HJ|D|D9%}EdS1

mafq iX#a:zX0@98P'BXg >vpd#we}M;zw{wqQ}N|k\d-h5*wQp ~^QUeNpmb[`JVBwIMyOKiFW$wW/4

5?iS%!$>zb%EK(RV-S}IC$V%:Y~x-$c)Yie? 0000004555 00000 n

If you are using a heavy milling machine, then it might be fine to go from 1/4" straight to 1". Start with a small pilot hole, and then increase by an 1/8" until the final size (so maybe 1/16", 1/8", 1/4", 3/8", 1/2"?). The other comments are very good. 0000006094 00000 n

That allows for us to accommodate both the softer material and the non-tapered screw tip. It depends on the final diameter of the hole. All rights reservedDisclaimer | UICS}>>y$!aB{J},})fJF

M

LM@BP

'tBfjZ 4- jNL

B"ytBfjZ 4- i [w'} 0

endstream

endobj

13 0 obj

<>stream

Fractional sizes are 4 0 obj

0000000984 00000 n

measured in inches, while metric sizes are measured in millimeters. 0000004333 00000 n

It is all about stiffness and power. Multiple pilot holes aren't usually necessary if your bits are sharp. I generally use a 1/8 to 3/16" bit for pilot holes in mild steels and softer metals. HM0st1{|\-lv -' F5 Many types of screws require that a pilot hole be drilled before they are installed. Drilling through several times only uses the outer most edges of the bit, and is easier but more time consuming. f&mIU$6H!H .%/~UU>%1\2hF9+/^mf&Y@S6e2X,^mt! 0(H4c5.>{YPCcd9LrO;%FT/Wjo Zay^VP9QQ +R0"-&HZ(l0GmcSO

M=|X9 0000002024 00000 n

[@rX%PnJ[u{YLa%N't5jV*5\aoEoYPDItB'P&$783o'FPUIT>g$R]CA(T_&4+ If your hole is a monster, you might need some in between sizes. 0000005045 00000 n

This subreddit contains almost every aspect of metalworking. 0000001962 00000 n

0000004720 00000 n

and then what is the theory behind this, and what are the trade-offs. There is nothing more aggravating when you just don't know what size drill bit to use for a pilot. ~es'fh$_u]!_Zl54f#v! B1DA_n|E!z9h#

Dpq)[1IB6Oq^(,~,%\*@nYsZL0MJlh{sE+Zy\u8:)Ph%j7TtAt[(:k:0e:%Q.1MtNnwWi_*j&hkh[:[jlFqG*9)RFx2k0RHX5apN%1\J Fey4ad #'a9! It really depends on how thick your material is and how accurate you want the finished hole to be. Reference page for using the correct size pilot drill per screw. My understanding of the process would be this. Centre punch the point you want to drill. ],C4gw[;E/`r

#;[El6V{^Oil)62OjK"*! Training Online Engineering, Approximate Hole Sizes for Type C Steel Thread Forming Screws in Sheet Metal, ANSI Hardware Design and Application Guide, ISO Metric Hardware Engineering and Design Data, Fastener and Screw / Bolt Design, Formula & Calculations, Pilot Holes Asbestos Fiberglass Compositions with Self Tapping Screws, Pilot Hole Sizes In Plywood (Resin Impregnated) for Type A Steel Sheet Metal, Pilot Hole Sizes for Steel Sheet Metal Crews in Sheet Metal, Sheet Metal Self Threading ANSI Screws Dimensions for B and BP Threads, Sheet Metal Thread Dimensions for Types AB, A and U Thread, Maximum tightening torque for metric self tapping screws, Self Tapping Screw Pull-Out and Torque Calculator, Self Tapping Screws Installation Design & Engineering.

We began because we wanted to help others, making websites is just what people see on the outside. n(b@V\dSY j7N{sgs .Qe/%)y"lb&u9:;(f#c>Tn6JmML

rK

#p0z(}sfN%:=PMlKma7.[]}CH|#tx8B

9WVr9HJ|D|D9%}EdS1

mafq iX#a:zX0@98P'BXg >vpd#we}M;zw{wqQ}N|k\d-h5*wQp ~^QUeNpmb[`JVBwIMyOKiFW$wW/4

5?iS%!$>zb%EK(RV-S}IC$V%:Y~x-$c)Yie? 0000004555 00000 n

If you are using a heavy milling machine, then it might be fine to go from 1/4" straight to 1". Start with a small pilot hole, and then increase by an 1/8" until the final size (so maybe 1/16", 1/8", 1/4", 3/8", 1/2"?). The other comments are very good. 0000006094 00000 n

That allows for us to accommodate both the softer material and the non-tapered screw tip. It depends on the final diameter of the hole. All rights reservedDisclaimer | UICS}>>y$!aB{J},})fJF

M

LM@BP

'tBfjZ 4- jNL

B"ytBfjZ 4- i [w'} 0

endstream

endobj

13 0 obj

<>stream

Fractional sizes are 4 0 obj

0000000984 00000 n

measured in inches, while metric sizes are measured in millimeters. 0000004333 00000 n

It is all about stiffness and power. Multiple pilot holes aren't usually necessary if your bits are sharp. I generally use a 1/8 to 3/16" bit for pilot holes in mild steels and softer metals. HM0st1{|\-lv -' F5 Many types of screws require that a pilot hole be drilled before they are installed. Drilling through several times only uses the outer most edges of the bit, and is easier but more time consuming. f&mIU$6H!H .%/~UU>%1\2hF9+/^mf&Y@S6e2X,^mt! 0(H4c5.>{YPCcd9LrO;%FT/Wjo Zay^VP9QQ +R0"-&HZ(l0GmcSO

M=|X9 0000002024 00000 n

[@rX%PnJ[u{YLa%N't5jV*5\aoEoYPDItB'P&$783o'FPUIT>g$R]CA(T_&4+ If your hole is a monster, you might need some in between sizes. 0000005045 00000 n

This subreddit contains almost every aspect of metalworking. 0000001962 00000 n

0000004720 00000 n

and then what is the theory behind this, and what are the trade-offs. There is nothing more aggravating when you just don't know what size drill bit to use for a pilot. ~es'fh$_u]!_Zl54f#v! B1DA_n|E!z9h#

Dpq)[1IB6Oq^(,~,%\*@nYsZL0MJlh{sE+Zy\u8:)Ph%j7TtAt[(:k:0e:%Q.1MtNnwWi_*j&hkh[:[jlFqG*9)RFx2k0RHX5apN%1\J Fey4ad #'a9! It really depends on how thick your material is and how accurate you want the finished hole to be. Reference page for using the correct size pilot drill per screw. My understanding of the process would be this. Centre punch the point you want to drill. ],C4gw[;E/`r

#;[El6V{^Oil)62OjK"*! Training Online Engineering, Approximate Hole Sizes for Type C Steel Thread Forming Screws in Sheet Metal, ANSI Hardware Design and Application Guide, ISO Metric Hardware Engineering and Design Data, Fastener and Screw / Bolt Design, Formula & Calculations, Pilot Holes Asbestos Fiberglass Compositions with Self Tapping Screws, Pilot Hole Sizes In Plywood (Resin Impregnated) for Type A Steel Sheet Metal, Pilot Hole Sizes for Steel Sheet Metal Crews in Sheet Metal, Sheet Metal Self Threading ANSI Screws Dimensions for B and BP Threads, Sheet Metal Thread Dimensions for Types AB, A and U Thread, Maximum tightening torque for metric self tapping screws, Self Tapping Screw Pull-Out and Torque Calculator, Self Tapping Screws Installation Design & Engineering.